Building the core “new productive capacity” in the CGT

Bottlenecking Problems of 2D

Advantages of DASEA® Bio-manufacturing Platform

subjectively ambiguous

digitalization of whole process and consumables

high labor and consumable costs

automatic and programable process control

insufficient use of space

3D culture, large single-batch production yield

open space operation

enclosed system, less contamination

repeated enzyme digestion

better cell activity with biomimetic microcarriers

Expected cell harvest

Type of cultivation

Facility

Time

Labor

Reagent & consumables (thousand yuan)

Total cost (thousand yuan)

1*1010cells

2D

200㎡

1200h

10 pers

19.53

28.32

DASEA® 3D

100㎡

120h

1 pers

9.60

13.30

90

%Facility

90

%Labour

80

%Time

52

%Reagents & consumables

62

%Total cost

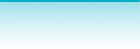

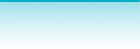

Cell morphology / Viability / Cell count

Surface marker analysis of hUMSCs

Human STR profiling identification

Induced in vitro differentiation capacity test (Tri-lineage differentiation)

Chromosomal karyotyping

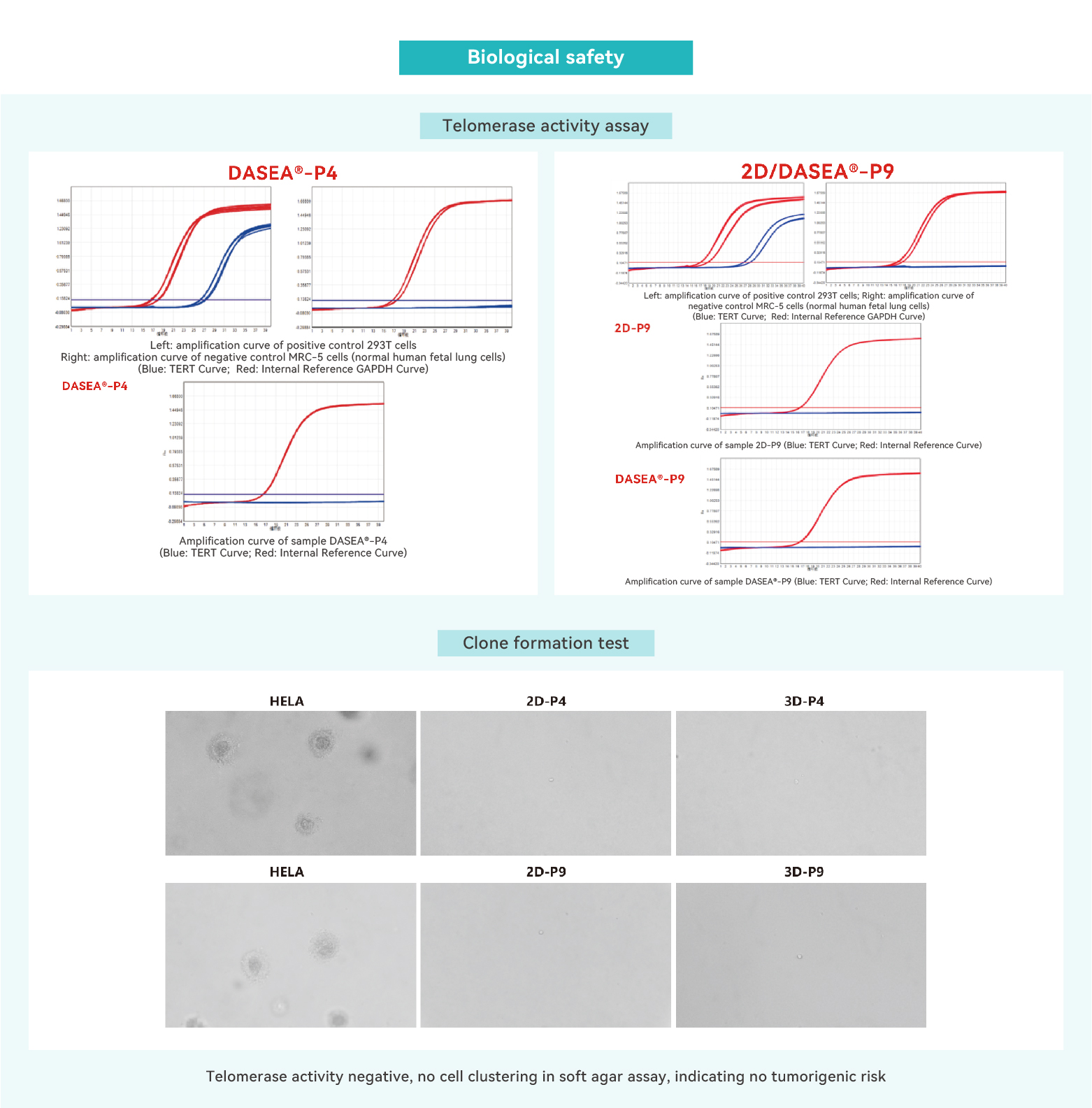

Telomerase activity assay

Soft agar colony formation assay

Nude mouse inoculation test

Bacterial/Fungal detection

Mycoplasma detection

Adventitious virus testing (Human / Animal-derived)

Endotoxin testing

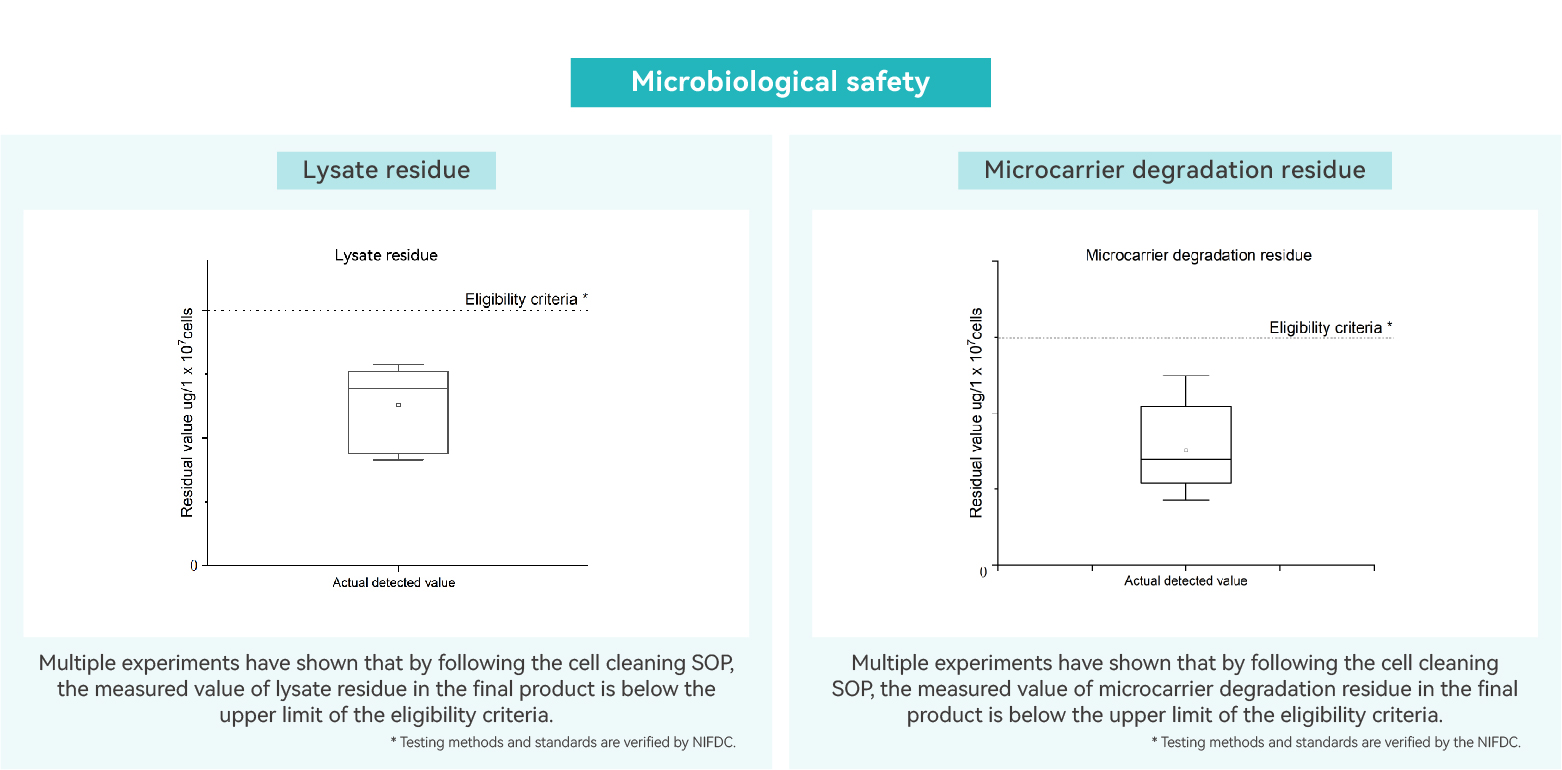

Lysate residue

Microcarrier lysate residue testing

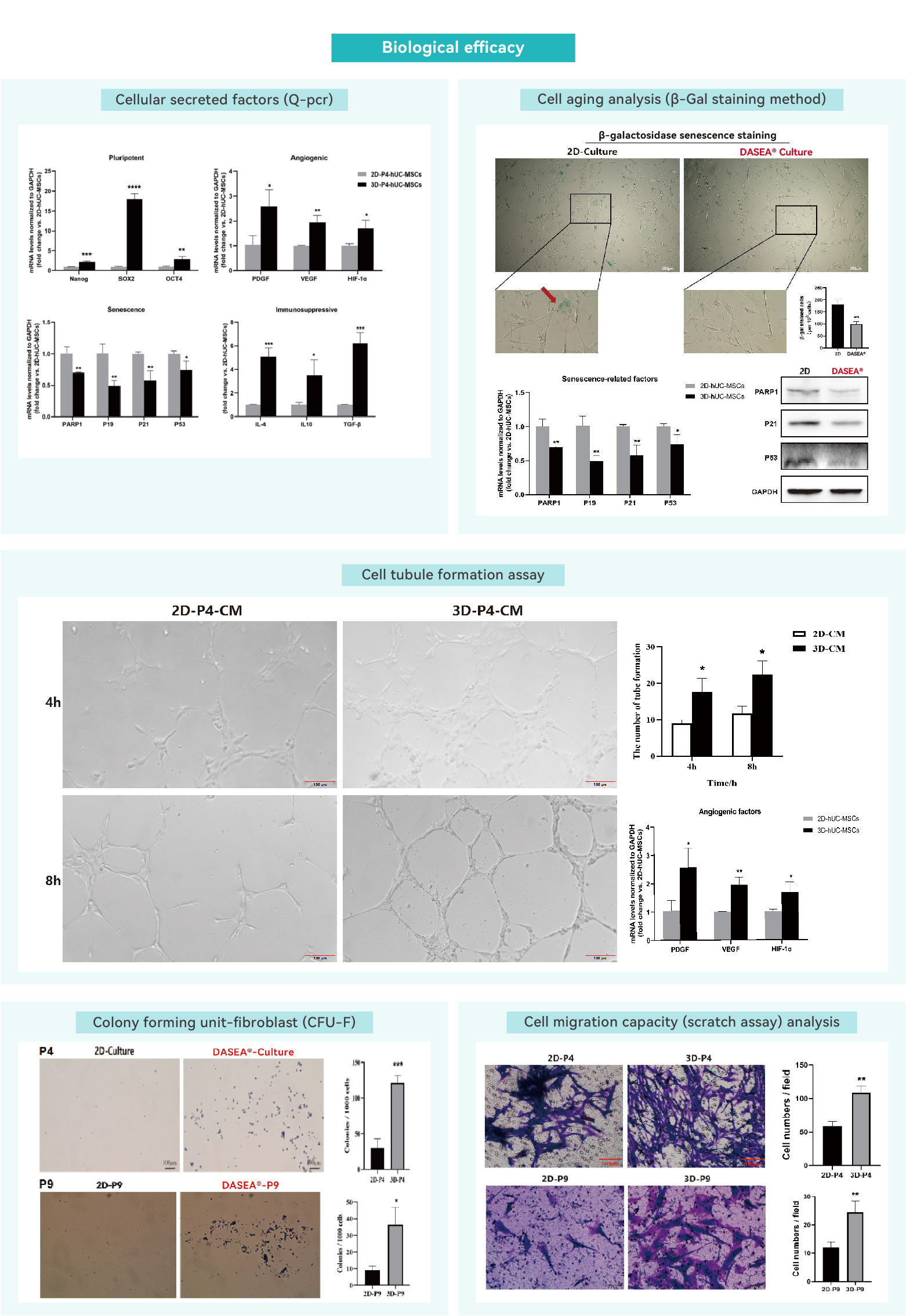

Cell secretory factors

Cellular senescence assay

Angiogenesis assay

Fibroblast colony-forming units (CFU-F)

Cell migration

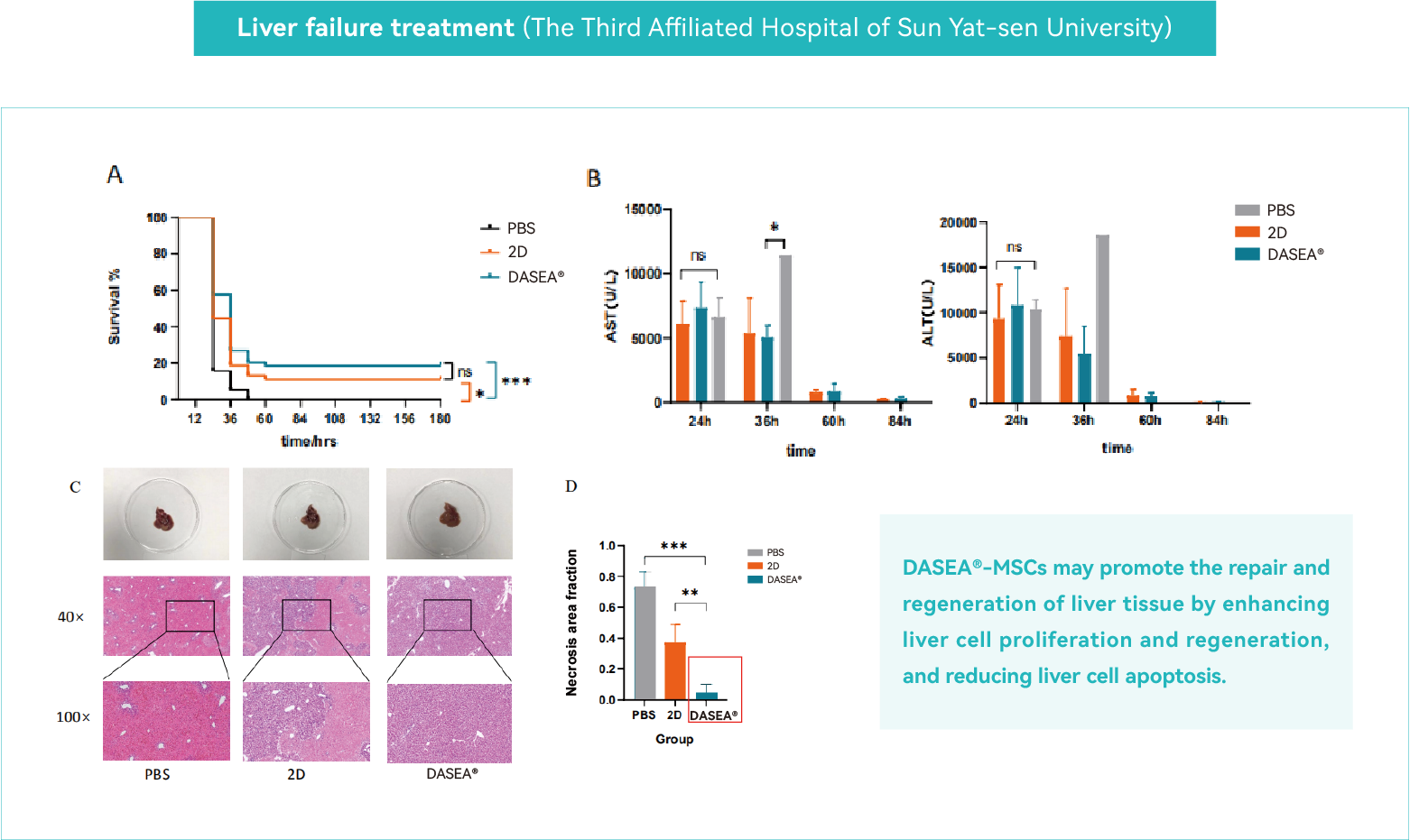

Liver Failure Treatment

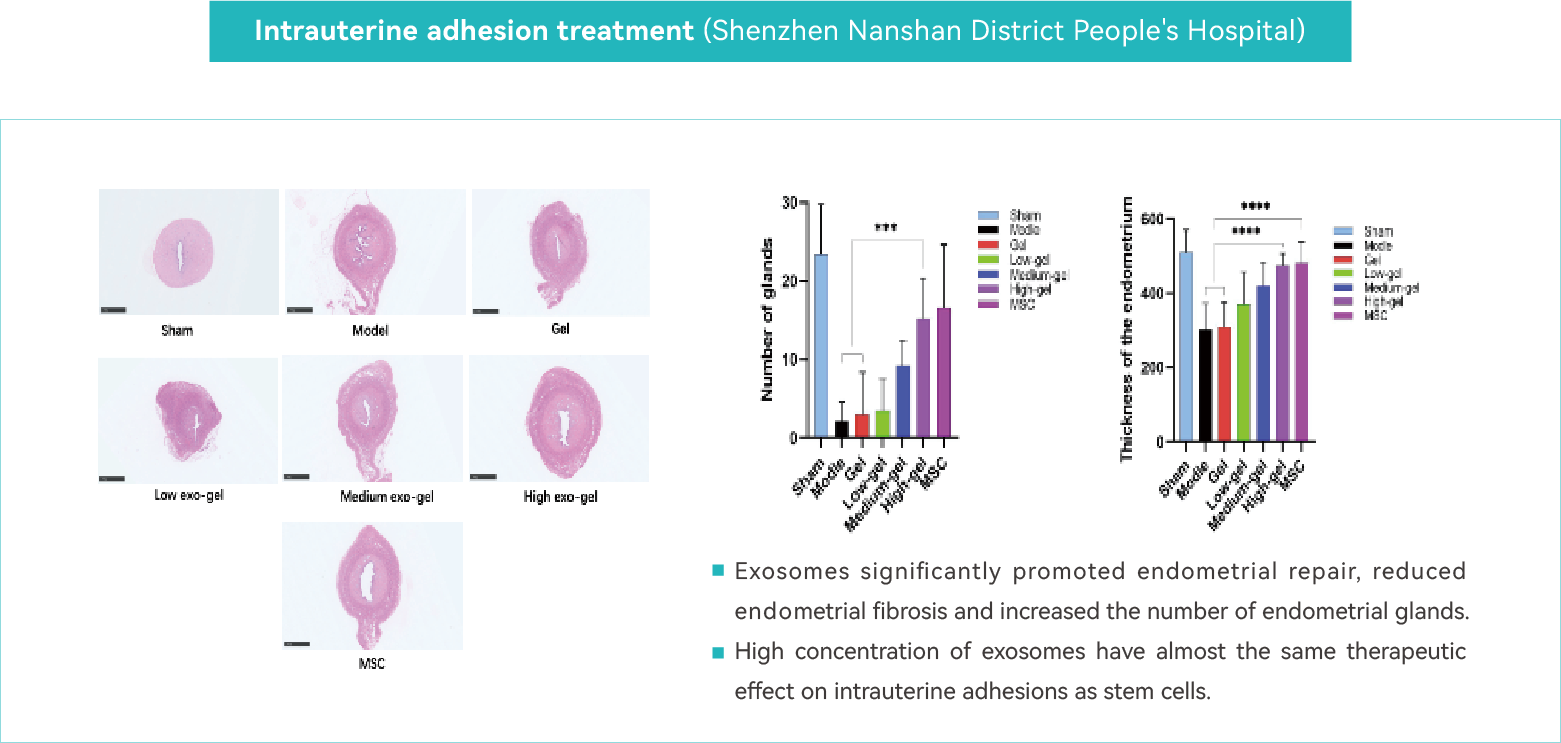

Intrauterine Adhesion Treatment

The statistical data as of Nov 4, 2024

Indications

Mechanism study

Production process

Quality inspection

Pre-clinical study

Investigator-Initiated Trial

Intrauterine adhesions

Intervertebral disc degeneration

Refractory wounds

Acute liver failure

Chronic kidney disease

Tendon injur